How to Maintain Your LED Fixtures for Optimal Performance

How to Maintain Your LED Fixtures for Maximum Performance By Aman | Updated on April 22nd 2025 LED fixtures are known for their long lifespan

Home » How to Prevent Yellowing and Cracks in LED Fixture Lenses

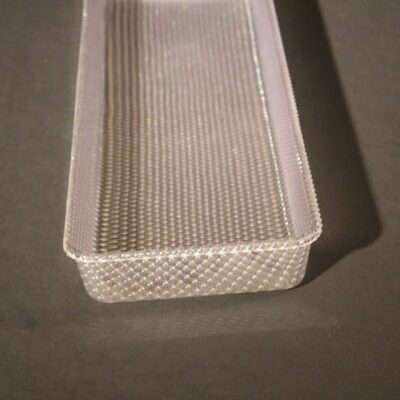

You’ve probably seen it before—those once-clear LED fixture lenses turning a hazy yellow or, worse, cracking apart like dry earth under the sun. It’s frustrating, especially when you’ve invested in quality lighting expecting it to last years, not months. Thing is, those blemishes aren’t just cosmetic. They can mess with light distribution, reduce efficiency, and make even the most modern spaces look neglected. And if you’re running a business or managing a facility, those small details matter.

Preserving the integrity of LED fixture lenses isn’t just about aesthetics; it’s about performance, durability, and cost-effectiveness. If you want your lights to do their job well and for longer, then knowing how to prevent yellowing and cracking is essential. Let’s dig into what causes it—and how to stop it from happening in the first place.

Yellowing happens when materials degrade—plain and simple. But the “why” behind it is a bit more layered.

UV Exposure

Sunlight is relentless. Even if you’re not using your LEDs outdoors, UV rays can still sneak in through windows. Over time, they break down the polymer chains in plastic lenses, causing them to discolor. The result? A yellowed LED light cover that diffuses light poorly and makes everything look oddly tinted.

Chemical Reactions

Exposure to cleaning agents, air pollutants, or even off-gassing from nearby materials can trigger chemical reactions in the lens. Think ammonia-based sprays or cheap solvents—these can react with the surface of the lens and speed up yellowing or cause micro-abrasions that collect grime.

Environmental Impact

Humidity, dust, grease, and airborne particles all take their toll. In kitchens, for example, a mix of heat, oil, and poor ventilation turns lenses yellow faster than you’d expect.

If yellowing is the slow fade, cracking is the dramatic breakdown. It doesn’t creep—it hits.

LEDs generate heat—less than incandescents, sure, but still enough. When that heat gets trapped due to poor ventilation or tight housing, it causes expansion. Then, when the light is switched off, it contracts. This constant stress cycle weakens the material over time, especially if the lens isn’t built for high-temperature tolerance.

Plastic gets brittle. It’s just a matter of time, especially if it’s not designed to flex or withstand long-term stress. Add age, environmental exposure, and occasional mishandling, and the surface starts spider-webbing before eventually cracking.

Start with the basics: not all plastic is created equal. Acrylics, polycarbonates, and other polymers each have their pros and cons.

UV-Resistant Materials

When selecting fixture lenses, opt for UV-resistant variants. These are formulated to withstand longer exposure to sunlight without discoloring. If you’re dealing with outdoor applications or high-sun areas, this is a non-negotiable.

Impact-Resistant Blends

Materials like modified polycarbonate are designed to absorb stress without breaking. These are especially useful in commercial spaces or high-traffic areas where accidental bumps are more likely.

LED technology has come a long way. These days, manufacturers are integrating better thermal stability and anti-UV coatings into their products by default.

Some new lens materials include multiple bonded layers, where the outer shell is built for scratch and UV resistance while the inner layer maintains optical clarity.

We’re not talking sci-fi here. These invisible films can significantly boost a lens’s resistance to dirt, heat, and sunlight. It’s like sunscreen, but for your LEDs.

Sometimes, the best defense is just plain cleanliness. But the method matters more than you think.

Do:

Don’t:

Over time, even light dust can magnify heat retention and UV exposure, hastening yellowing. A monthly wipe-down goes a long way.

A lot of issues stem from how the fixture is installed. If the housing’s too tight or the bulbs are improperly aligned, stress concentrates on weak points in the lens.

Also, avoid placing lights near vents or appliances that emit heat, like ovens or HVAC units. Over time, external heat adds up.

While UV-resistant materials are your first line of defense, adding a layer of UV-blocking film or spray can make a real difference—especially in outdoor or skylight-facing installs.

You can find UV sprays that work similarly to how sunglasses block sun rays. Just make sure they’re optically clear and designed for polycarbonate or acrylic.

Heat kills—literally, in the case of LEDs.

Ventilation Matters

Make sure your fixtures allow for adequate airflow. Fixtures with metal housing or integrated heatsinks help dissipate heat better than fully enclosed plastic shells.

LED Positioning

Keep the LED chips and lenses separated wherever possible. Heat buildup near the lens shortens its lifespan dramatically. Look for fixture designs that keep heat-generating components isolated.

Smart Upgrades

If you’re upgrading older fixtures, use retrofit kits that come with improved heat shielding or add thermal barriers yourself.

LED lenses are like the eyes of your lighting setup—when they’re cloudy, cracked, or yellow, everything suffers. But the good news? It’s avoidable.

By choosing high-quality materials, installing fixtures properly, performing regular maintenance, and applying a few smart upgrades, you can prevent those dreaded yellowed LED light covers or cracked LED lenses from ruining your setup. Lighting durability isn’t just about buying good products—it’s about protecting your investment long-term.

For facilities, offices, schools, and even homes, finding replacement or custom LED diffusers that resist yellowing and cracks is simpler than ever. Fluorolite Plastics provides a wide range of tailored lighting solutions that are built to last—and look good while doing it.

Yellowing happens primarily due to prolonged UV exposure, chemical reactions with cleaning agents, and heat buildup inside the fixture.

Run your finger gently across the surface. If you feel sharp edges or see lines that don’t wipe away, it’s cracked. Dirt usually forms patterns or spots, while cracks have sharp, linear edges.

Not really. You can try polishing lightly, but most discoloration is permanent. It’s best to replace the lens with a UV-resistant version.

Nope. Avoid anything with ammonia, alcohol, or strong solvents. Stick to gentle soap and water to preserve clarity and structure.

Yes. Look for UV-resistant lens materials or fixtures with built-in protective coatings. Many modern options are engineered for long-term clarity.

Replace the lens as soon as possible. Cracks spread quickly under heat. You can prevent further damage with proper ventilation and by lowering ambient temperatures.

Ideally, every 4–6 weeks. Dust and grime trap heat and UV, which leads to faster yellowing and brittleness.

Replacement light diffusers can be molded or cut to custom sizes, especially for hard-to-fit fixtures. Fluorolite Plastics offers tailored solutions for both residential and commercial needs, making it easy to match old or discontinued models.

How to Maintain Your LED Fixtures for Maximum Performance By Aman | Updated on April 22nd 2025 LED fixtures are known for their long lifespan

Top 5 Benefits of Upgrading to LED Fixtures in 2025 By Aman | Updated on April 22nd 2025 As energy costs rise and sustainability becomes

How to Retrofit Old LED Fixtures with Modern Covers By Aman | Updated on April 15th 2025 LED lighting has pretty much taken over the

"We've Got You Covered" and Trace n'Fax are Registered Trademarks of Fluorolite Plastics, LLC. © 2011-2024 All rights reserved Fluorolite Plastics